With the transportation industry rapidly changing, we wanted to create a playbook that will help educate and guide organizations through the industry. Learn everything today’s fleet leaders need to know, highlighting industry problems, future trends, tools and strategies, and much more.

Industry Problems

Leaders in the trucking industry face a myriad of problems, all of which can have huge impacts on their business — whether that be good or bad. Through talking with our clients and employees, we’ve pinpointed three major problems we believe stand above all and threaten organizations: increasingly slim margins, aversion to new technology, and increasing industry regulations.

Slim Margins

The trucking industry is currently on the cusp of a major technology evolution. Just a decade ago, truck drivers and logistics managers depended on fax machines, paper logbooks, and maps for communication. Now, those in the trucking industry would be left to the wayside if they were without smartphones, laptops, electronic platforms, and GPS systems. In fact, the role of technology is increasing efficiencies in everything from fuel economy to communication.

Because technology is evolving so rapidly, being locked into a long-term contract with a transportation software provider can leave you using outdated technology and being passed by the competition. High up-front costs and fees for software cut into margins and build up fast.

When it comes to the retail propane and fuel oil industries and the bulk long haul commodity industries, up-to-date technology is especially important because of the high variance in routes and number of drops, along with the sheer amount of information and data that needs to be organized — among many other things.

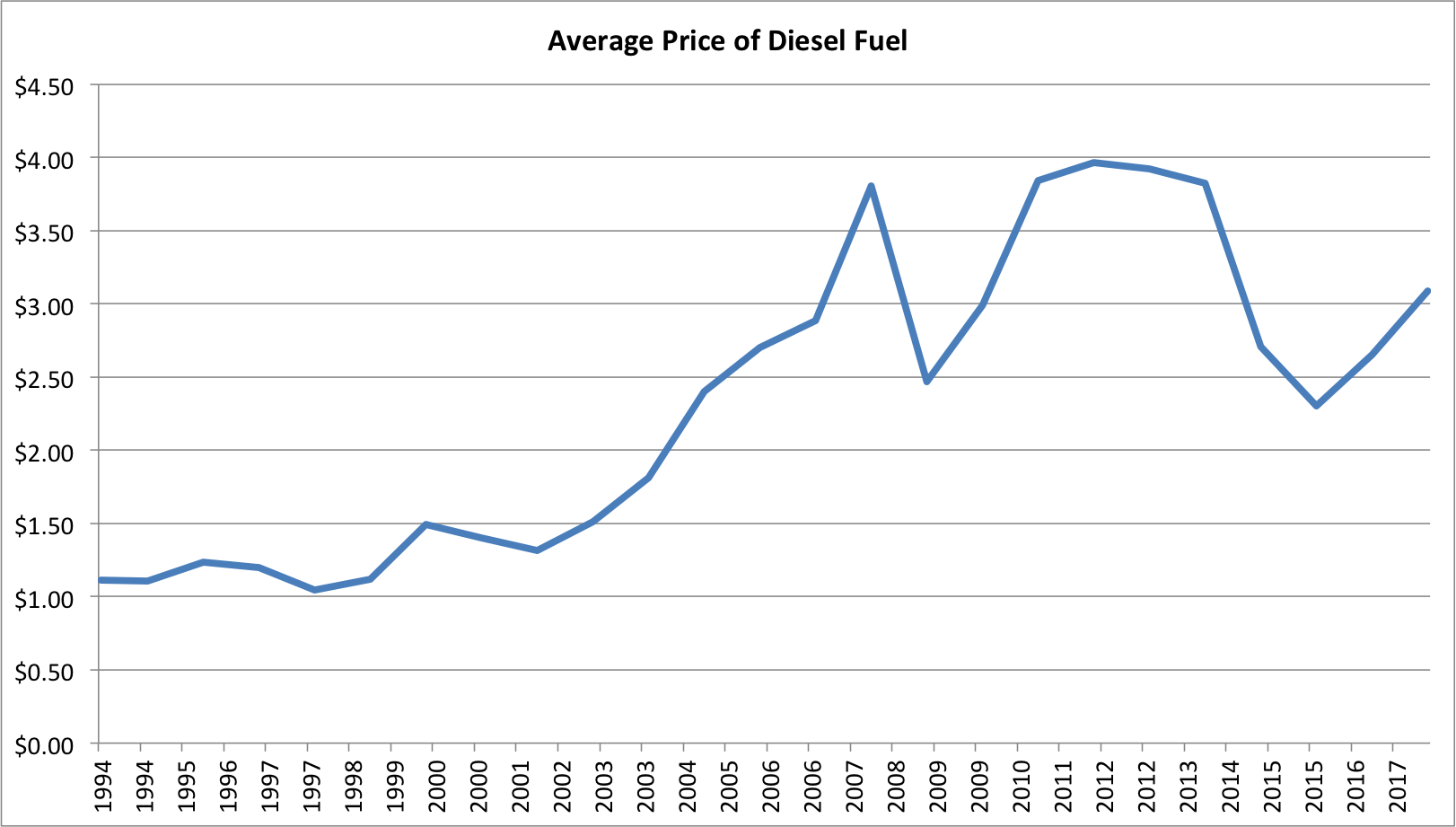

Driver routes are constantly changing while on the road, so every route needs to be optimized to ensure efficiency is at the highest possible level and get margins as high as possible. If routes are not, drivers will be traveling unnecessary miles, wasting diesel, and increasing wear and tear on the fleet — all of which add up to additional expenses that can be eliminated if quality transportation software is implemented. Increasing diesel prices are putting more pressure on trucking companies to find ways to save money. Effective software is able to adjust routes on the fly and optimize drivers’ routes to maximize loaded miles and eliminate deadhead. Increased capacity means increased margins, benefiting everyone involved.

In the transportation industry, there is a vast amount of information and data to keep track of — invoices, available hours for drivers, load/ticket information, per-delivery costs — the list goes on. All of this data and information is necessary for legal and compliance reasons, evaluating the efficiency of your business, and making decisions on your future, so it is extremely important to have processes in place to collect and store it in an easily accessible, centralized location.

For example, today’s technology has the ability to eliminate paper run tickets and messy handwriting; instead, drivers are able to print electronic run tickets in the field and send all load data back to your portal in real-time. Automation minimizes data entry and human error, leading to much more accurate records.

With quality transportation software, data regarding route efficiency, fuel consumption, and other information along the same vein can be automatically collected and stored, allowing you to analyze it and predict future needs — rather than taking guesses at such things as fleet size needed or the number of staff/drivers required. The right technology can streamline your operations by minimizing trucks, miles, and staff needed to complete jobs, greatly increasing your margins and setting you up for growth.

Aversion to New Technology

With all of the changes that are happening in the industry in regard to technology, some people are wary of the advancements and elect to follow the saying “if it ain’t broke, don’t fix it.” The problem is, that way of conducting business will soon be cast to the wayside. Technology allows organizations to effectively manage and analyze their operation, streamlining it and increasing profits. For example, a standard GPS that takes a driver from point A to point B cannot compete with current navigation technology that can create optimized routes in real-time with multiple drop locations and maximize loaded miles — and that’s just a basic feature.

The biggest objection to adopting new technology — especially for smaller companies — is the belief that it is too expensive and not worth the investment. However, compared to other operating costs, such as diesel and permits, technology is a relatively small expense that can have a huge return on investment. The right technology can prevent drivers from traveling unneeded miles and wasting diesel — the highest expense of transportation services. Technology is advancing too rapidly to sit idly by — you either adopt it or get left behind.

Industry Regulations

New regulations are constantly being introduced to the trucking industry and while they are designed to increase safety, they can be costly to implement. One of the biggest regulations to hit the industry in recent history is the ELD mandate. All truck drivers, including owner-operators and company drivers, are required to use electronic logging devices that meet Federal Motor Carrier Safety Administration (FMCSA) standards. This mandate was put into place to replace the paper logbooks some drivers use to record their compliance with Hours of Service (HOS) requirements. The FMCSA states that ELD will annually prevent 1,844 collisions, 562 injuries, and 26 deaths.

If not already stocked with the proper equipment, fleets will have to purchase the technology and install it. The ELDs track hours and gauge them against the HOS requirements. The current limits set an 11-hour driving rule, in which a driver may drive up to 11 hours total before they are required to take a 10-hour break, and a 14-hour on-duty shift rule, which starts as soon as a driver switches their status to on duty or driving. The tricky part about the 14-hour on duty rule is that as soon as the driver switches statuses to on duty or driving, the 14-hour clock starts ticking and once it is up the driver is required to take a 10-hour break. So even if a driver puts their status to drive, drives for 4 hours, and switches their status to off duty for 10 hours, they are still legally required to take a 10-hour break.

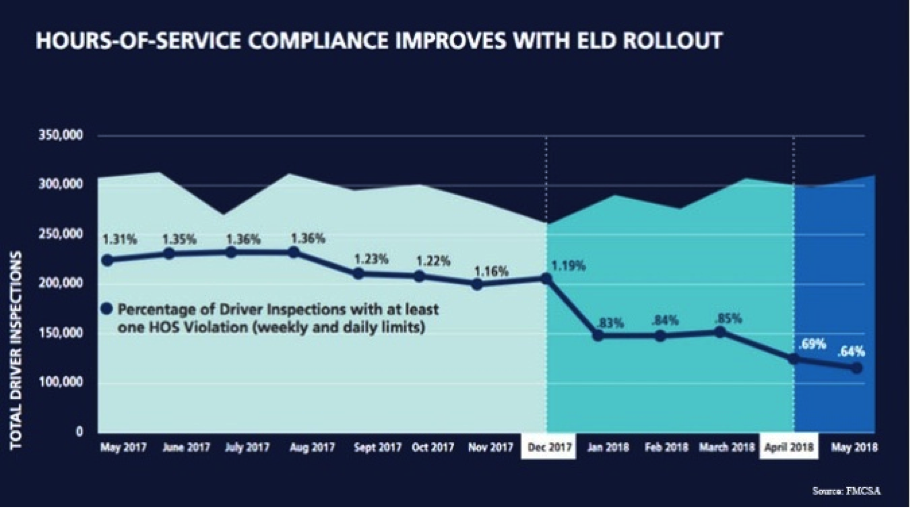

The mandate has been in effect for over 10 months now, so we can see the effects it’s had on trucking fleets. A report released by FMCSA showed a sharp decrease in HOS violations immediately following the ELD mandate coming into effect.

While the mandate has had some positive effects, various problems have come along with it as well. Some of the devices used to track drivers’ HOS have been operating at sub-par levels, such as not accurately tracking the hours they drive, mileage, or their location. These miscues can lead to penalties down the road.

Even when devices aren’t malfunctioning, there are enforcement problems. The former head of the FMCSA stated that the “FMCSA was not remotely ready for this regulation to take effect, which was unfortunate. In fact, they didn’t even begin training local and state law enforcement until November of last year.”

The problems and pressures that the HOS rules put on drivers has caused the FMCSA to consider making changes to the current rules. According to Safety and Health Magazine, the official magazine of the National Safety Council, the FMCSA is considering the following revisions:

- Expanding the current 100 air-mile “short-haul” exemption to 14 hours on duty from 12 hours on duty, to be consistent with rules for long-haul truck drivers.

- Extending the current 14-hour on-duty limitation by up to two hours when a truck driver encounters adverse driving conditions.

- Revising the current mandatory 30-minute break for truck drivers after eight hours of continuous driving.

- Reinstating the option for splitting up the required 10-hour off-duty rest break for drivers operating trucks equipped with sleeper berth compartments

In addition, separate petitions requesting relief from HOS rules are open to input. These are:

- To allow covered commercial motor vehicle operators one rest break – for up to three consecutive hours – during every 14-hour on-duty period (filed by the Owner-Operator Independent Drivers Association).

- To allow covered CMV operators to use multiple off-duty periods of at least three hours in place of taking 10 consecutive hours off duty (filed by TruckerNation.org)

Finally, the U.S. Department of Transportation (DOT) recently released an 80-page document titled “Preparing for the Future of Transportation: Automated Vehicles 3.0,” or “AV 3.0” for short. It expands the DOT’s voluntary guidance on the development of what they consider “automated vehicles.”

The document goes into detail on principles, levels, roles, and the future of automation. While these regulations are not mandatory to follow, they do provide a glimpse into what could be coming in the future. If you want to see a full breakdown of their document, we took a deep dive in this blog post.

Research

The transportation is rapidly changing, so predicting future trends can help organizations plan ahead. The price of fuel looks to be on the rise, implementing the ELD equipment seems to have some laggards, and the current capacity crunch isn’t being helped by the driver shortage.

Fuel Prices

As stated earlier in this piece, diesel prices are rising. In the past few years, diesel had come down in price by substantial amount, but the price is trending upwards again. See below for the average diesel price each year since 1994.

On average, diesel fuel accounts for 39% of your total operating costs for the year -- by far the largest operating cost; driver salaries are the second leading cost at accounting for 26% of costs. Clearly, if routes are not optimized fuel will be wasted and operational costs will skyrocket -- especially as diesel prices continue to climb.

With quality transportation software, organizations are able to complete more drops on fewer miles -- greatly increasing profits. The investment in current technology will pay dividends shortly down the road.

ELD Mandate Compliance

With regard to the ELD mandate, there are still some laggards in implementing the new equipment. According to a survey conducted in December of 2017 -- just a week before the ELD deadline for drivers who did not already have an AOBYRD -- approximately 75% of the 420 fleets surveyed were ELD compliant. Of the remaining respondents, 68% said that they did not plan on meeting the ELD deadline in time, while 31% stated they planned on never installing an ELD at all.

The punishments for noncompliance may seem minimal at first glance, but they can quickly build up. Drivers face fines if they are caught, along with being placed out of service for up to 10 hours for each violation of the guidelines. If your ELD happens to malfunction, you only have 8 days to repair or replace the device or risk fines. These fines and out of service placements stack up quickly, keeping you off of the road and taking money out of your pockets.

Capacity Crunch and Driver Shortage

The increased demand for shipping services, coupled with the historic driver shortage, has created the perfect storm. PLG Consulting estimates that the industry is short about 60,000 drivers and that will increase to 160,000 by 2026 if nothing changes.

The main factor for this shortage is the average age of the current workforce and the younger generation’s disinterest in driving. When current drivers are retiring, younger workers are not entering the industry to replace them.

Driver turnover rates are also at extremely high levels. PLG Consulting stated that, “big and small TL fleet turnover from 2016 to 2017 ranged from 64% to 90%.” This is not a sustainable level for any business. Due to the demand for drivers, organizations are being forced to increase driver pay to attract more of them. Depending on the carrier, driver pay has increased anywhere from 10-20% this year, according to Odyssey Logistics.

Organizations looking to keep the capacity crunch under control are investing in fleet management technology in order to maximize the drivers that they do have and minimize other operating costs.

Strategies

Real-Time Analytics

Having the ability to analyze the effectiveness of your operation in real-time is invaluable in today’s constantly changing industry. Dispatchers are able to evaluate the routes drivers are currently following and determine if a different path would be more efficient, increasing profitability. Supervisors are also able to ensure their drivers are compliant of the routes that are set by seeing them in real-time.

Real-time analytics afford companies the ability to utilize their entire fleet much more effectively. In the same way drivers can be monitored in real-time on the road, available hours are also able to be evaluated -- which allows for scheduling on the correct number of drivers every time rather than trying to make an educated guess. Overall, real-time analytics enable organizations to be confident in their operations in that they are getting hard-data on efficiency and effectiveness that can be used to make quality, data-backed decisions -- not conclusions based on best judgements.

Reporting

In the transportation industry, reporting is an extremely important aspect to ensure jobs get completed and the operation is compliant in all areas. Having a system of records in a centralized location gives easy access to information when required.

For example, paper run tickets are outdated and can lead to problems down the road. Messy handwriting and loss of tickets happen too often and put organizations at risk. Electronic ticketing allows drivers to send all load data back to a portal in real-time, aggregating all load information in one location to be stored and easily found in the future.

Compliance documents can also be electronically stored in a consolidated location, giving drivers peace of mind that when they need to present documentation, they will always have access. These simple processes can make a big difference in an fleet’s bottom line by ensuring regulations are followed, liabilities are eliminated, and documents can be found at anytime very quickly.

Hi-Tech Integrations

With every quality transportation platform comes the opportunity to add-on hi-tech integrations to advance your operations even further. Individual driver performance and compliance can be improved in various ways. In-vehicle driver coaching gives drivers real-time feedback while on the road through equipment that outputs verbal coaching or a buzzer when the driver violates the rules you specify. Rules can be setup to reduce unwanted driving behaviors such as speeding, idling, or not wearing a seat belt.

Integrations can also have risk and safety reporting for drivers. Risk and safety scores can be assigned to drivers based on a variety of factors such as:

- Speeding

- Seatbelt usage

- Braking habits

- Degree of corner turn

- Acceleration

- After-hours vehicle usage

Instant accident notifications are also available, with technology saving all data leading up to the impact during an accident, similar to an airplane’s black box.

SaaS and Subscription Pricing

Software as a Service (SaaS) is on-demand software using cloud storage. A SaaS product can be presented as a subscription model, meaning you are not required to sign a long-term contract. Rather, you can pay month-by-month and evaluate product performance against your fleet’s needs on a regular basis. The pricing structure is very straightforward and simple, allowing companies to confidently predict their expenses.

One of the major benefits of trucking software being offered with a subscription pricing model is the savings associated with it. The up-front costs are generally much lower than committing to a long-term contract, along with lifetime cost of ownership being lower as well. IT costs for data are reduced because the data is stored in the cloud rather than your physical on-site servers -- eliminating overhead costs such as mainframe hardware, maintenance, and repairs.

The subscription model offers flexibility in that users have the ability to adjust capacity or discontinue the subscription if it no longer meets their needs. This ensures that the provider is always putting out the best technology and updates so that they retain happy customers. You are able to evaluate your options every month and determine if you are satisfied with your current provider. If you are not, all you have to do is cancel the subscription.

Cloud Hosting

With cloud hosting, accessibility is a huge advantage over traditional hosting mediums such as servers. Because everything is hosted online, anyone who has permissions to access the platform can do so from anywhere in the world (provided they have the proper security and broadband width to ensure performance). This creates a mobility that has never been present in the trucking industry before -- documents, data, and other records can be accessed by anyone, in any place, at any time. With accessibility comes peace of mind that anything stored within the cloud will be automatically backed-up by the services provider and restored if an issue arises, such as user error.

Updates to cloud hosted platforms are made frequently due to the ease at which they can be implemented -- giving you the newest features and functionality at all times. Organizations will not be stuck on standby waiting for the updates to take place because they can be made remotely and extremely quickly. If a problem arises with the software, patches can be made immediately to alleviate the issue, rather than requiring a technician to come and fix the problem.

The advantages cloud-based technology has over traditional methods, such as on-premise technology, are innumerable. If you feel that the the philosophy “if it ain’t broke, don’t fix it” fits with your current technology situation, take a look at our cloud vs. non-cloud logistics technology comparison matrix and you might just change your mind.

Tools

Welltrax

Welltrax is a cloud based bulk commodity trucking software solution for transporters hauling commodities such as crude oil, propane, sand, water, NGL, chemicals, gravel, and more. The platform increases fleet and operational efficiency by reducing deadhead, allowing drivers to be emailed their loads rather than calling in, and sending pick-up and drop-off locations -- among many other things.

Because it’s hosted on the amazon AWS cloud and offers a SaaS subscription pricing model, new features and product updates are constantly being implemented -- you can see what’s in the works here. Installation, configuration, and reporting is handled directly through the Welltrax system, making it easy to transition to from any platform and ensuring that it is setup correctly. Some key features include:

- Centralized system to create, manage and standardize operations

- Intuitive split load management

- Assisted dispatch and route optimization

- Real-time visibility of the fleet and ticket information

- Customer formatted templates and automated reports

To evaluate whether the investment in Welltrax is worth it, you can use this free Welltrax ROI calculator and then get a free 45-day trial to test it out yourself.

SmartDrops

SmartDrops is the solution for propane and fuel oil fleets, tying together back office systems and route planning capabilities to create the industry’s most comprehensive delivery management system. The platform builds better, faster routes for your drivers to follow -- stopping efficiency leaks.

SmartDrops automatically dispenses fuel, computes invoices, and updates your portal and back office equipment, minimizing data entry and error -- all while simultaneously minimizing truck, miles, and operational staff and maximizing efficiency. Just like Welltrax, SmartDrops offers a SaaS subscription pricing model and is hosted on the Amazon AWS cloud -- allowing many exciting upcoming updates to be seamlessly rolled out once completed.

The platform offers:

- Back office synchronization

- Delivery control

- In-vehicle navigation

- Advanced technologies

- End user portal

Geotab

In order to stay in line with the new electronic logging device mandate, it is essential to have a reliable ELD that ensures your compliance. Geotab offers the industry leading ELD device -- plus it integrates seamlessly with Welltrax, giving you the best of both worlds.

The device will vastly cut down on paperwork, saving much needed time and money, reducing overall administration costs. It also allows you to increase the efficiency of your record keeping and inspections, making sure the correct information is easily accessible when needed.

Success Stories

Guardian Logistics Solutions was frustrated about working with a logistics platform that couldn’t deliver effective load and ticketing management. Guardian was frustrated with their current platform because they were spending too much time trying to change how they operate to fit the system, rather than using a platform that adapted to them. Searching for a solution that truly met their needs as a bulk transportation provider, they came upon Vertrax.

As soon as the new platform was deployed specifically for them, the organization saw an immense change. They had previously been using manual spreadsheets as a backup due to their lack of trust in previous platforms, but after one week with Vertrax they stopped. Guardian was able to see every step of their loads on the road in real time.

Guardian’s transportation manager Dylan Scott, stated “Welltrax has allowed our organization to operate as we felt it should. We no longer have to adjust to our system. Welltrax adjusts to us.” You can access the full case study here.

Another success story is with Thompson Gas. The company was growing rapidly through acquiring smaller regional propane companies and integrating them into their current operations, but ensuring the fleet is the right size is crucial to maximizing the bottom line of these acquisitions -- too many delivery trucks making too few deliveries in an inefficient manner resulting in high delivery costs, cutting into the bottom line. Thompson Gas needed software that could make their operation much more efficient and streamlined, putting an end to unnecessary miles and trucks.

Vertrax was able to deliver a platform that allowed the operational centers to fully understand

how best they can deliver on customer demand for propane in the most efficient way possible. The ability to optimize routes in real-time and maximize the utilization of company assets dramatically increased Thompson Gas’ bottom line.

George Koloroutis, COO of Thompson Gas, said “Few, if any investments we’ve made have delivered such immediate, real and measurable results. In dollars and cents, payback exceeded our most optimistic projections. We delivered 17% more gallons with the same number of bobtails and traveled 70,000 fewer miles. At over $4.50 per mile, you do the math!” Access the full case study here.

Comments from other satisfied customers:

“Vertrax provides the most technologically advanced and integrated Mobile solution in the fuel industry. Their Mobile Platform is light-years ahead of the competition – and Vertrax will keep it that way. The Return on Investment is massive and they are a great company to partner with.”

“Delivery efficiency is something we strive for every day. Vertrax’s SmartDrops is an invaluable tool to help us manage our deliveries. The ROI is exponential as we learn new ways to use the software and related products every day.”

Download The PDF Version Of The Agile Fleet Playbook Today!

Experiencing any of these problems and want to learn more about the strategies and tools you can use to fix them? Contact us today and we'd be happy to help!