The propane industry has been operating the same way and using the same equipment for far too long. This outdated equipment puts your operational efficiency at risk as well as your profit margins. It also gives you a competitive disadvantage as many propane marketers have embraced and invested in new tank monitoring technology.

In this blog, we break down why “Remote Ready Gauges” are outdated and we outline the key issues that come with using them. We also suggest what to replace them with to increase your overall operational efficiency and visibility.

Downfalls of Remote Ready Gauges

“Remote Ready Gauges” are a twenty-year-old technology that rely on the more than 50-year-old technology of a manual float. The propane industry has been using these gauges as “standard equipment” since their introduction in the 1930s.

Remote Ready Gauge manufacturers report a +/- 5% accuracy based on total tank volume, which results in 20-30% inaccuracy when tanks drop below 25%. For example:

- 250 gallons (25%) full – reading will vary +/- 50 gallons (+/- 20% margin of error)

- 150 gallons (15% full) – reading will vary +/-50 gallons (+/- 33% margin of error)

And this example is for a “fully functioning” gauge, not taking into account wear down over time which further decreases accuracy.

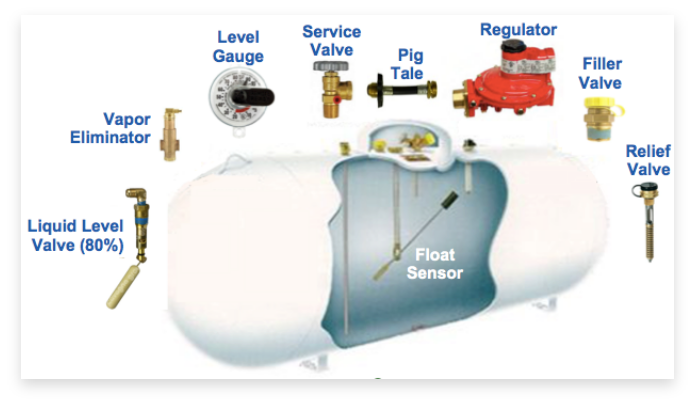

Another contributing factor to these inaccurate readings is that the gauges rely on a combination of multiple mechanical parts to operate. Even if these parts all work perfectly together, the reading on the tank will still be inaccurate.

Here’s a look at what each of the above pieces of equipment does:

- Liquid Level Valve: Used during the filling process to determine when the tank is full.

- Vapor Eliminator: Used during fuel transfer.

- Level Gauge: This gauge reads the percentage of remaining fuel.

- Service Valve: This is the main on and off valve. Used to shut off in case of an emergency.

- Pigtail: Small copper tubing connecting the service valve to the Regulator.

- Regulator: This device controls the flow of propane so your appliances work properly.

- Filler Valve: Used to fill the tank, the cap should always be kept on.

- Relief Valve: This device prevents the integrity of the tank from being compromised.

Vertrax recently diagnosed faulty equipment and prevented a potentially disastrous situation for a West Coast Marketer through the use of our Tank Monitoring Service. In short, a faulty gauge was identified that was previously reading tank levels at the industry-standard safety level of a propane tank (80% full), while in reality, the tank was actually up to 97% full – creating a huge liability for the marketer and putting individuals at risk.

The Solution: Vertrax Tank Monitoring Service

Rather than relying on a combination of mechanical parts that wear down over time and provide inaccurate readings no matter how perfect they’re operating, Vertrax Tank Monitoring Service leverages sonar sensors that have no moving parts and therefore do not wear down.

Vertrax Tank Monitoring Service gets EXACT liquid level readings of tanks instead of measuring the empty space in a tank to get a reading. This allows for extremely accurate and consistent readings of tank levels.

With the simplicity of the technology deployment, there is no need for tank modifications and the solution is deployable for:

- Any tank

- Any age

- Any condition

- Any location

Finally, this technology is powered by Amazon AWS and by leveraging multiple communication methods for failsafe data transmission, tank data can always be accessed from anywhere on either the Vertrax Tank Monitoring Service app or dashboard.

Don’t rely on “technology” that is so outdated and unreliable that it puts your operations at risk.

Vertrax Tank Monitoring Service is the simple solution that allows for unparalleled visibility and gives you the power to make confident business decisions.

Interested in seeing what Vertrax Tank Monitoring Service can do? Access our free on-demand webinar where Kevin Jaffe, VP of Tank Monitoring, shares a demo and dives into the solution even more.

Already know you want to try it out for yourself? Sign up for our Pilot Program!